Redesigned and now offered with instant center adjustment!

This torque arm is now supplied with pivot brackets that allow (2) settings to allow easy instant center adjustment. By simply moving the torque arm into the next location you can automatically change the instant center point of the vehicle. This is very crucial on low to mid horse-power cars and can easily lower 60-foot times.

1993-1997 Models- This unit is designed to clear with factory exhaust manifolds and factory y-pipe. The drive shaft loop may not clear aftermarket y-pipe set-ups, please confirm before purchasing.

1998-2002 Models- This unit is designed to clear vehicles running Kooks long tube headers with a Kooks y-pipe. It will not clear the factory y-pipe and may not clear aftermarket y-pipes that bolt into the factory manifolds. Please confirm fitment before purchasing.

Front Drive Shaft Loop- UMI Performance offers this torque arm with a NHRA legal drive shaft safety loop. Please note the front drive shaft loop will clear all 93-97 models and 98-02 models with Kooks long tube header systems and Kooks y-pipe. It will NOT clear 98-02 models with stock y-pipe and most y-pipes bolting to stock exhaust manifolds, drive shaft loop will clear 93-97 models with stock y-pipe. Only choose a front drive shaft loop if your vehicle is a 93-97 with factory y-pipe or 98-02 running Kooks set up or you have confirmed this will fit your application.

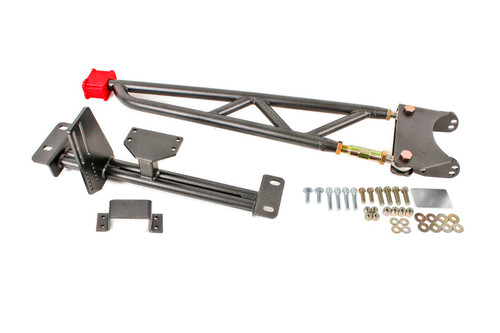

Description- Track abuse, street abuse, or just flat-out abuse, this torque arm is designed to handle it all! Eliminate unwanted traction problems by adding a UMI Performance Tunnel Braced Mounted Torque Arm. This aftermarket torque arm replaces the flimsy weak stock torque arm adding strength, rigidity and eliminating flex. This torque arm design relocates the front torque arm mounting point off the transmission tail shaft protecting the transmission and preventing damage. A shorter torque arm improves weight transfer on acceleration. General Motors tail shaft mounted design works great for a stock driven vehicle however it is not designed to take abuse. This set-up bolts to existing floor pan holes using 0.500” thick mild steel CNC machined mounting plates and metric grade 10.9 hardware. The complete cross brace is constructed of 0.120” thick rectangular tubing and attaches to the torque arm using 0.250” thick mild steel mounting pivot plates with Grade 8 hardware. The torque arm is attached to the supplied cross brace using an Energy Suspension polyurethane bushing set-up on both the supplied cross brace and torque arm (See Picture Below). Polyurethane was chosen as a mounting point to keep road noise at a minimum and eliminate unwanted “clunks” found with other set-ups available. The grease-able polyurethane bushings absorb road irregularities and protect noise from entering the passenger compartment. The rear mounts feature 0.375” thick CNC machined mounting plates and are appropriately drilled to fit your stock rear as well as aftermarket 12-Bolt and 9” Rear-end housings. This set-up requires no welding or drilling and can be installed with basic hand tools; this is a complete bolt-in design.

Torque Arm Benefits:

- Removes torque arm from transmission tail shaft protecting transmission

from damage

- Eliminates wheel hop and solves traction problems

- Reduces front end nose dive during braking

- Allows for on-car pinion angle adjustments

- Polyurethane bushings designed to keep road noise at a minimum

- Front mounting point utilizes a grease-able pivot point

- Bolt-on design requires no welding or drilling!

Build Features:

- Constructed of 1.250” x 0.120” DOM Seamless Steel Tubing

- Front Cross Member uses 0.120” x 2.000” Rectangular Tubing

- TIG Welded 4140 Chrome Moly Tube Adaptors

- On-Car Adjuster Built using 4140 Chrome Moly Steel and Heat Treated

for Maximum Strength

- Front Pivot Mount is supplied with Grade 8 Mounting Hardware and

Locking Nuts

- All Polyurethane Bushings are Grease-able to Prolong Bushing Life

- All Mounting plates are CNC Machined to insure hole to hole accuracy

- Rear Mounting Plates use 0.375” Thick Mild Steel and are designed to

fit Stock as well as 12- Bolt and 9” Rear-End Housings.

- Rear Mounts feature Solid QA1 ¾” Rod Ends and are attached using

Grade 8 Hardware

- Brilliant Durable Powder Coat

Chrome Moly- Chrome Moly version uses 1.250" x 0.095" 4130 Chrome Moly steel feature 100% TIG welded process. This adds increased strength and reduces product weight, recommended for vehicles running 10.50’s and faster in the ¼ mile.

Rear Torque Arm Hardware Kit- We highly recommend purchasing a new hardware kit if running this torque arm on a stock rear-end, Strange or other similar rear-ends that use a straight through bolt design. OEM torque arm bolts will work however are slightly too short and may not work correctly. If you are running a Moser Engineering 12-Bolt rear-end this kit is not needed, you must reuse hardware supplied by Moser Engineering. This kit however is recommended for the Moser 9”.