With today's technology and advanced ECUs, stick shift racers continue to push the envelope with more and more HP and torque. Aggressive street-style multi disk clutches can compound the issues found with keeping a transmission and drivetrain together at extreme power levels, as well - and then there is the other enemy: weight! Guys are making 1500+ whp in 'racecars' that weight 3300+ lbs!

Here at Tick, we have been campaigning our own stick shift shop car, the "Grubb Worm." The transmission you're about to learn about has been tested in our car for four seasons now with a best ET of 6.61 @ 216 mph at race weight of 2800 lbs. The car makes an estimated 2000 whp.

No core required, this transmission is sold complete!! If you have a core housing, shift rail components, and all other various pieces of hardware to complete this build contact someone on our sales staff at 336-719-0599.

Freight shipping is included to a freight terminal local to you. Choose from the drop down for different shipping options.

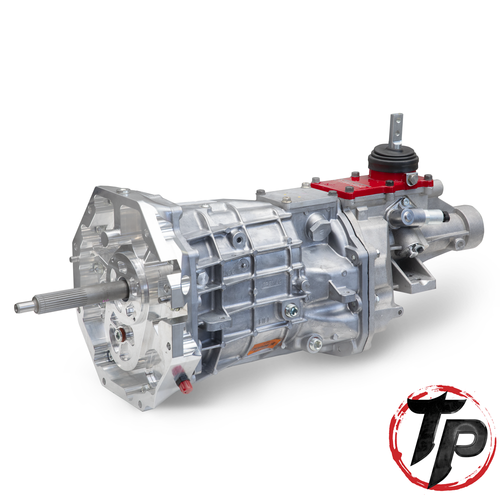

Here is what you get!

- Media blasted core T56 case

- G-Force face plated gear set w/ 2.71 first gear ratio

- 9310 G-Force 30 spline output shaft

- New bearings and seals

- New snap rings throughout

- Tick Performance Billet Front plate w/ choice of Input Speed Sensor or Mechanical Fluid Pump

- Tick Performance Hi-Flow Trans Pump kit (with filter and fittings) (Input Speed Sensor Option ONLY)

- Tick Performance input speed sensor (Input Speed Sensor Option ONLY)

- 1-2, 3-4, and Reverse Bronze fork pads

- Liberty's Gear billet interlock plate

- Billet interlock guide bolts

- Tick Performance billet aluminum 1-2 shift fork

- Tick Performance billet aluminum 3-4 shift fork

- Custom Modified 5-6 / Reverse shift rail assembly

- Custom Modified shifter gate assembly

- CNC machined reverse lockout piston

- Custom machined aluminum 5-6 driven gear delete spacer

- Modified main case for larger rear counter shaft bearing

- Modified 5-6 extension shaft

- Modified tail housing for larger output bushing and seal

- New OEM reverse syncro keys, springs, and blocker ring

- Various new or core components to complete transmission assembly

- Bronze shifter cup bushing

- Billet aluminum skip shift delete plug

- 5qts of fluid GF2000 75w140

- 10lbs of weight reduction compared to a standard T56

About the Input Speed Sensor

We have found that proper clutch selection is critical to the life of your transmission as well as the rest of your drivetrain. For these extreme drag cars, this means an adjustable clutch. Having the ability to 'hit' the tire softer even with more power or RPM (and leave the line more like an automatic) will not only help keep your transmission in-tact, but it will also make the car easier to handle and much more consistent. You'll also have an advantage on days where the track surface or conditions aren't the greatest. To fully take advantage of an adjustable clutch, you need to monitor input shaft speed vs. engine speed. With the input speed sensor found in this transmission, you can monitor this data through your modern EFI system and use it to make the proper adjustments much more quickly versus trying to make changes based on sound or feel.

About the Billet Front Plate

The most common failure we have seen on high horsepower T56 and TR6060 transmissions is a damaged input gear and the mating gear of the countershaft. This can be an expensive repair as those are two of the most expensive parts found inside to be replaced. These gears become overheated, whether it be due to lack of fluid from hard acceleration (the fluid rushes to the rear of the trans during hard acceleration) or simply the extreme power. Being the most forward located gear in the box adds to the fluid supply issues. Also, the input gear and the mating gear of the countershaft are under load in all gears (except 4th which is 1:1 ratio) so it is easy to understand why it is the most common gear to fail. The Tick Performance Billet Front plate includes a much-improved bung and sprayer design which consists of a machined and welded bar that extrudes into the transmission, coating 2nd, 3rd, and 4th gears more evenly with oil.

· Improved Bungs and Sprayer system coats 2nd, 3rd and the input gear as well as the mating cluster gears in oil

· Improved rigidity, better gear mesh, and engagement

· O-ring sealing for a leak-proof design

The Tick Performance Billet Front Plate for T56 and T56 Magnums is machined here in house in Mount Airy, North Carolina. The billet design vastly improves strength, which decreases gear deflection and enhances performance.

In our testing, we’ve found better gear engagement and improved gear wear patterns. It handles torque deflection better, too, improving the life of your transmission. The billet plate includes the Tick Performance Hi-Flow Trans Pump kit (with filter and fittings).

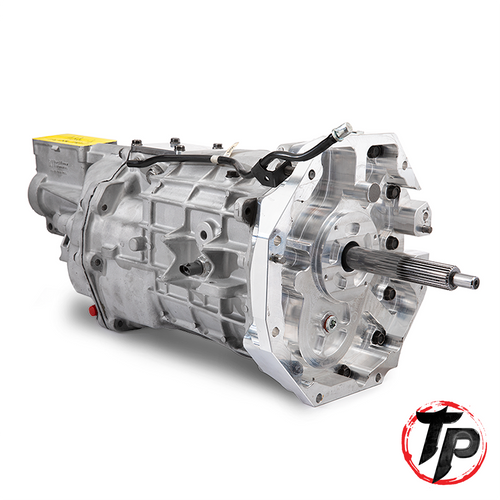

About the G-Force Gear SET

The gear set found in this transmission build uses 9310 material for exceptional strength. The gears have a re-engineered design and tooth profile as well as extra gear width wherever possible. When talking about extreme power levels and drag racing stick cars, it is inevitable that you will break something inside of your transmission eventually as nothing is bullet proof. By design, the G-force gearset is much easier to disassemble (this translates to cheaper labor costs for future rebuilds.) All bearings are either slip fit or can be pressed off of their respective shaft without damage, unlike a regular T56 or TR-6060. For example, if you break an input gear, you don't have to buy a new bearing as long as the bearing is still good. The counter shaft is a two piece design as opposed to one piece on a standard T56 or TR-6060, so if you break 3rd gear for example, you only have to buy the section of counter shaft that has third and fourth on it, not the full assembly. This is a racer minded gear set!

About the 4 speed Conversion

T56 and T56 Magnum transmissions have two overdrive gears. Fourth gear is 1:1 ratio just like 4 speed transmissions in the old days. By removing these gears we are able to shave 10 lbs, but more importantly we have redesigned the reverse lockout piston and modified the 5/6/R shift rail assembly so that reverse is now located in the gate originally occupied by 5th. Combined with our modified reverse lockout piston and your ECU to control (just as the oem ECU would control the reverse lockout) we have made it impossible to miss 3rd gear by going too far to the right with the shifter. A shift from second to third can now have a strong directional push to the right and the lockout will act as a barrier or guide to direct the shift straight into 3rd gear!! That same strong directional push to the right that you as the driver will exert greatly reduces your chance of a 1-2-1 shift. Many have simply removed 5th and 6th gear from T56 transmissions over the years for the weight savings, but they left an empty gate where 5th and 6th were located which left you as the driver to guide the shift into the right 'slot' or you were relying on the detents of the transmission and spring load of your shifter to line the shift up in hopes that you don't accidentally go back into first gear.