- For factory stock or mild HP upgrades to 600HP

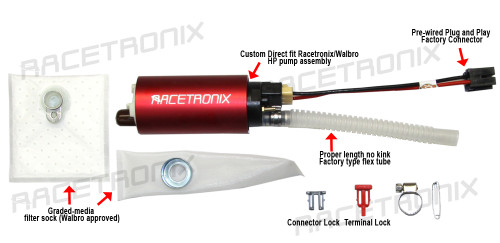

- Custom Racetronix / Walbro pump

- Venturi feed system - Racetronix exclusive

- Red anodized billet T6 aluminum pump assembly

- Racetronix to GM Teflon wiring harness

- High-pressure non-kinking G.M. fuel tube

- Custom 30 micron filter sock

* FOR USE IN 1999-2002 CARS WITH FACTORY ORIGINAL PLASTIC FUEL TANK AND PLASTIC FUEL MODULE ONLY!

F99 Fuel Pump Assembly

The FPA-001B is recommened for factory HP upgrades to 600HP @ 58PSI using the factory lines and fuel pressure regulator. HP support may vary for N/A or F/I motors. Please factor in a 20-25% safety margin between what your motor needs and what your fuel system can supply. Our FPWH-001 wiring harness is recommened to maximize performance. Please contact your local Racetronix dealer to discuss your fuel requirements.

Why a universal pump can not be properly used in the 1999-2002 f-body:

The 1999 & up LS1 F-body cars have a pump that is inside a plastic fill-bucket. The fill-bucket is equipped with two inlets on the bottom. The equalization checkvalve is used to fill the bucket when the level of fuel in the tank is greater than in the bucket. The equalization checkvalve does not allow fuel to exit the bucket. The venturi system's inlet is a combination checkvalve and powered suction system. The factory pump supplies pressurized fuel via a small tube which feeds a calibrated jet inside the venturi system. This jet of fuel shoots across the base of the checkvalve inlet thereby creating a suction effect which draws more fuel from the bottom of the tank through the filter sock. This venturi system keeps the bucket full all the time even when the fuel tank is almost empty. A full bucket keeps the pump immersed in fuel regardless of the tank level so that when the tank is low on gas and you are doing some hard cornering or acceleration the pump does not run dry and start aerating (air bubbles) the fuel. This happens as the fuel sloshes from side to side in the tank leaving the center low on fuel. This can cause detonation and possible engine damage. The 99+ F-LS1 cars with plastic tanks have no baffling in them so the bucket is very important. The bucket also allows the car to operate with lower fuel levels in the tank due to its scavenging effect. The fill-bucket improves motor crank-to-run time as the priming time is reduced under most conditions. The return line feeds the pressure regulator on the fuel module which diverts fuel back into the bucket so that the unused fuel also helps keep it full at all times. Keeping the pump constantly immersed in gas within the bucket can extend the pump's life by not allowing it to be exposed to open air. Open air within the tank contains moisture and in time will cause the pump to rust / seize up especially if left to sit for long periods of time without the tank topped-up (i.e. winter storage).

What sets the Racetronix F99 pump assembly apart from others?

The Racetronix F99 pump assembly is shrouded in a T6 anodized aluminum housing. This housing simulates the proper outer diameter of the factory pump for proper fitment.

WARNING: Some copy-cat pump kits use a foam rubber sleeve which will deteriorate using today's pump and race gas which can contaminate the fuel module. This can cause pump failure and engine damage. GM does not use rubber parts in late model fuel systems so why introduce this potential menace now?

A factory-style fuel tube is clamped to the pump's outlet for added reliability under high operating pressures. When the fuel module is placed back in the tank it must compressed causing the tube to bend sharply which can cause standard rubber hose to kink and fail. The fuel tube is highly resistant to the additives in today's pump gas which will attack and dry out even the best R9 and R10 rubber fuel lines. This is why G.M. uses them as OE equipment.

WARNING: Some copy-cat pump kits use a longer generic flex-tube or rubber hose which can bind up and puncture once the module is compressed back into the tank.

The Racetronix F99 pump assembly is equipped with an outlet which supplies the factory venturi system which is required to keep the factory system fully functional! All other pump solutions to date do not have this feature which requires a hole be punched in the bottom of the fill-bucket thereby dangerously disabling its functionality.

WARNING: Some copy-cat pump kits use questionable venturi fitting insertion processes which could lead to internal pump contamination and pre-mature pump failure. Racetronix insertion process was perfected and proven after two years of development and field testing prior to production. Racetronix has stress analysis tests to backup our process.

The Racetronix in-tank pump wiring harness eliminates the need for a wiring adapter or splicing which can be unreliable and can cause performance loss. One end the Racetronix in-tank harness has a Walbro connector that plugs directly into the pump and the other end has a Delphi connector which plugs directly into the sender. Teflon wire is used just like in the factory because it is the most resistant to gasoline and its additives. We upgrade the gauge of wire used from the factory to reduce voltage loss which maximizes pump performance. All Racetronix harnesses are assembled using our computerized crimp-quality monitoring system and then circuit checked for the utmost in reliability. A truly plug & play wiring solution. Due to the age of some F-LS1 cars much of the in-tank connectors are black / corroded. The Racetronix harness replaces all these questionable components.

WARNING: Some copy-cat pump kits use fuel resistant plastic wire which is not as durable as Teflon. As well they do not have a new connector installed on the end of the in-tank harness which forces the customer to re-use the questionable old factory connector body. This has also let to some confusion as to the proper polarity forcing some people to remove their tanks again in order to fix the problem!

Quality Pumps

The Racetronix F99 pump assembly is based on Walbro gerotor pump technology utilizing the most powerful armature and gear set currently available. Walbro has set the industry standard in high-performance in-tank pumps. Walbro pumps are QS9000 certified and are used as OE equipment in many production performance vehicles such as the C5 and C6 Corvette. Walbro's gerotor design is able to maintain high pressures while providing high volumes as well. This is done by squeezing the fuel out between two gears instead of pushing it like most factory vane pumps do. (i.e. factory F-LS1 pump). This positive displacement design makes high-performance Walbro pumps small, light weight, quiet, efficient and reliable.