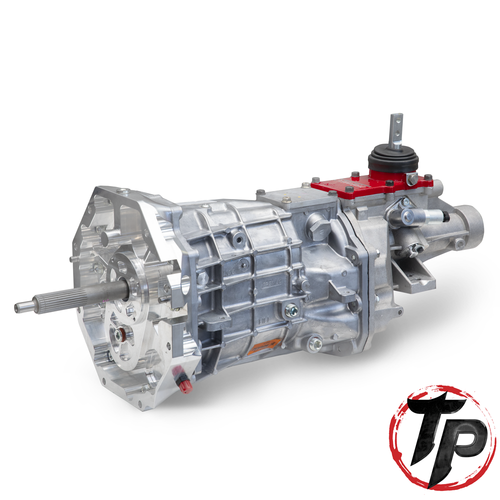

Tick Performance has partnered with PPG to offer a line of Ford specific Magnum XL as a Sequential Transmission! We utilize PPG's sequential system and numerous gear sets to offer you the perfect sequential transmission for your application! Whether you want to line up at the drag strip, cut down on your lap time, or simply make shifting easier we have the gear ratio for you! Assembled in-house by our professional transmission technicians who have assembled some of the quickest H-pattern transmissions in the world!

Utilize the amazingly quick-shifting performance of a sequential transmission in Ford specific Magnum XL package. No need for extensive reworking or custom fabrication you normally find with sequential transmissions in aftermarket cases. This transmission includes a SFI certified bellhousing and transmission crossmember.

Sequential System

With a speed of operation usually only found in F1-type applications, Pfitzner Performance Gearboxes sequential systems integrate with modern 32-bit ECUs to provide closed loop strategies that are capable of providing sub-70ms gear shifts. This impressive speed of operation gives the PPG system a unique advantage over its competitors, optimizing the shift phase to allow the return of power through the transmission as soon as the dog is pre-engaged. This function can only take place by using the most advanced of measurement sensors available: the GILL Blade 360° rotary position sensor. This state-of-the-art measuring device allows PPG’s Tremec sequential gear system to map and track absolute position of the dog-rings to provide levels of barrel and selector position accuracy that were previously unobtainable. It also supplies next-gear stable calibration tables with precise and repeatable data. By achieving a seamless shift phase - coupled with low-energy strategies - the PPG system circumvents a requirement for 100% ignition cuts when the gear change is made, meaning that many of the forces that unsettle a chassis during a gear-change operation are eliminated. This results in a far more balanced and predictable handling car and consequently, a better overall performance.

Benefits

- World’s only 6-speed sequential system for TREMEC transmissions

- High HP and Torque capacity

- Gear sets drop directly into OE casings

- Paddle shift upgrade option

- Ideal for cars used on track and street

- Unique PPG dog design

- Quieter operation and easy shifting

Gear Ratios

| 2.148 | 1.561 | 1.228 | 1.000 | 0.875 | 0.777 |

| 2.148 | 1.561 | 1.228 | 1.000 | 0.797 | 0.634 |

| 2.437 | 1.611 | 1.228 | 1.000 | 0.875 | 0.777 |

| 2.437 | 1.611 | 1.228 | 1.000 | 0.875 | 0.634 |

| 2.946 | 2.071 | 1.438 | 1.000 | 0.875 | 0.634 |

| 2.946 | 2.071 | 1.438 | 1.000 | 0.875 | 0.777 |

| 2.589 | 1.841 | 1.438 | 1.000 | 1.000 | 0.777 |

| 3.255 | 2.148 | 1.561 | 1.000 | 1.000 | 0.857 |

| 2.407 | 1.872 | 1.522 | 1.000 | 1.132 | 1.000 |

Shift Lever & Gear Indicator (Included)

Gearbox Control Unit Might Be Required

This is the standard option for sequential gearboxes and allows the driver to operate with a pull for upshift and push for downshift. The lever allows very good installation and very smooth gear changes can be calibrated. The normal operation of the system will be via a solid rod; linkage or Series 4 push pull cable. Each of these options comes with its benefits and enables the design to be optimized within the boundaries of the OEM installation.

The gear lever option has several variations available and calibrators decided based on the ECU systems ability as to what is best suited. As A company we always encourage end users to use a closed loop installation taking full advantage of any DBW (drive by wire) capability the ECU system may have.

No ECU

- This is the most basic installation and can yield great performance if the driver has the ability to modulate the throttle on up and down shifts simulating an engine cut. The method has its inherent risks and can allow power on shifts that can destroy the dog rings and put excessive strain on the drivetrain.

Load Cell - Strain Gauge

- The system is very basic in its functionality but does provide some great installation and results with again the caveat of no protection should the driver miss shift during the shift phase.

Closed Loop Gearshift Operation with Integrated Rotary Position Sensor

- This system is the optimal configuration for any sequential gearbox installed using lever operation. There are many variants, but to cover the main topic we will consider a gear lever with a load cell and sequential gearbox with a position sensor to read the rotary position of the sequential selector barrel.

Paddle Shifters

Gearbox Control Unit Might Be Required

The paddles in motorsport applications are used to shift or actuate the next gear, either up shift or downshift. This function is via a small switch mounted into the paddle assembly. When a signal is sent, the ECU reacts to its input and signals the gearbox to change gear. This function works to actuate the gear shift pneumatic cylinder mounted on the gearbox.

Air Shifted

- This option is in most cases a bolt on addition to the existing system and allows seamless integration to the OEM platform.

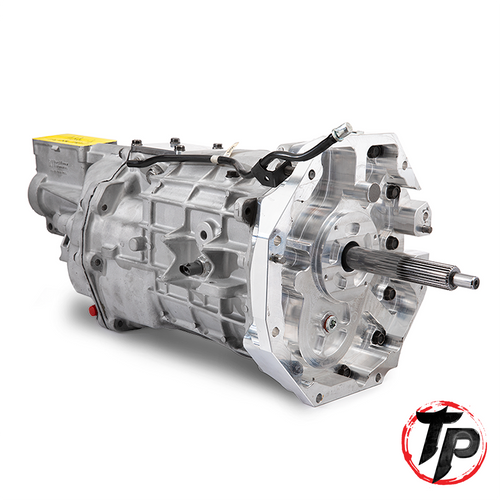

Billet Main Case

Take your transmission to the next level with a PPG Billet case. PPG's billet main case is CNC'ed from a solid piece of 6061-aluminum and machined to tighter and more precise tolerances than a standard cast case. The case increases rigidity and cuts down on deflection, allowing for better mating of gears, better wearing characteristics, and overall better strength. They are designed to withstand 1500-2000hp setups! With power requires more strength and this billet case has it.

Benefits

- Input speed sensor port / option to have it supplied

- Dog / gear inspection ports

- O-Ring Sealed

- Speedflow Breather

- More rigid case – better shift feel and reliability

- Machined to suit the sequential to fit right in without needing to machine the case

- Optional Temperature Sensor

- Optional 2-in-1 sensor – Temperature and Oil Condition

- Made from billet 6061 Aluminum

- Mounting clips to suit DTM Plugs for wire harnesses

- High strength magnetic drain plug

- Mounting points on case

- One port can be used to return oil straight to the input shaft

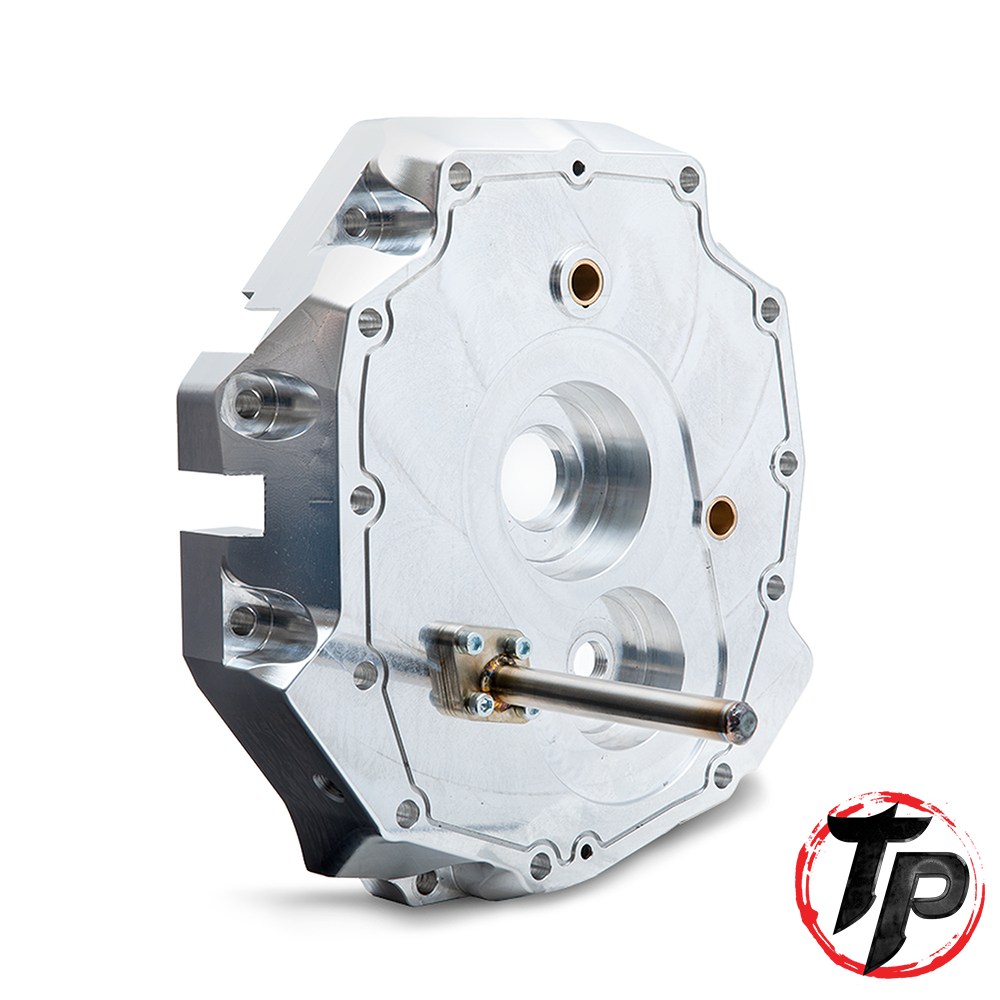

Billet Front Plate & Sprayers (Included)

The Tick Performance Billet Front Plate for the Ford Magnum XL is machined here in house in Mount Airy, North Carolina. The billet design vastly improves strength, which decreases gear deflection and enhances performance.

In our testing, we’ve found better gear engagement and improved gear wear patterns. It handles torque deflection better, too, improving the life of your transmission. The billet plate pricing includes the Tick Performance Hi-Flow Trans Pump kit (with filter and fittings).

Benefits

- Improved Bungs and Sprayer system coats 2nd, 3rd and 4th gears in oil

- Improved rigidity, better gear mesh, and engagement

- O-ring sealing for a leak-proof design

- Can be used with either T56 or Magnums (includes necessary adapters)

Powder Coating

This transmission will look brand new when it arrives at you door, but if you're building a show car you may opt for powder coating, which is much more durable than paint. Available in Black Satin or Silver. This option adds 10-15 days to your turnaround time. NOTE The inlet port for the slave cylinder feed line may need to be clearance to allow proper seating of the slave cylinder.

Micro Polish

Micro polishing consists of rotating a part at relatively slow speeds. As the part rotates through the machine, non-abrasive media makes contact on all surfaces of the part. At Tick Performance, our Micro polishing has two processes. The first process introduces a cutting solution into the media. The cutting solution very slowly smooths the surface of the part from the gentle wiping of our non-abrasive media. The second process is the polishing itself that utilizes a different type of solution. This solution acts as a varnish that makes the metal part look like it has a chrome finish. The Tick Performance Micro polishing adds horsepower gains, achieving higher RPMs while simultaneously lowering operating temperatures and adding longer service life.