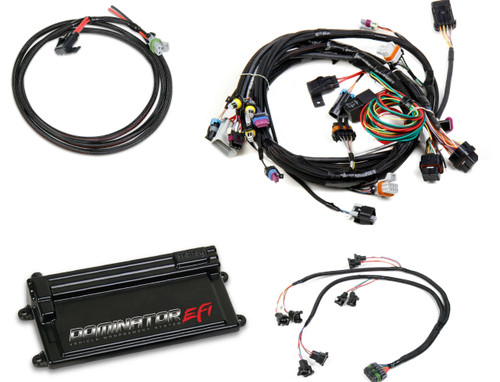

Fits conventional push rod Ford Engines, with EV1 Injectors. DominatorÌâå¨ EFI Vehicle Management Systems are intended for non-emissions street and racing engine applications. In addition to the transmission control, drive by wire, and dual wideband oxygen sensor options, DominatorÌâå¨ systems have nearly unlimited capabilities to control any power adder, input, or output you can throw at them. Need to run a turbocharged, nitrous injected 8 cylinder running water-methanol injection? No problem with DominatorÌâå¨ EFI. How about control a 4L80E transmission as well as the fuel and spark on your street rod? No problem. There are also enough inputs and outputs to allow the DominatorÌâå¨ VMSs to serve as their own data acquisition and control module. The DominatorÌâå¨ VMS will eliminate the need for additional controllers as they are all contained in this one unit. The only thing limiting the DominatorÌâå¨ Vehicle Management System is your imagination! Features: Dominator EFI base kits come in several product variations to fit most popular domestic V8 engine applications such as; LS, SBC/BBC, SBF, BBF, and Chrysler engines Kits include the following: Dominator ECU, USB cable, ECU Power Harness, Engine Main Harness, EV1 Injector Harness, Bosch Wideband, ECU mounting hardware Integrated electronic transmission control - Operates GM 4L60E and 4L80E transmissions, Ford AODE and 4R70W with more to come in the future Integrated drive by wire throttle body control - Can control two drive by wire throttle bodies. Compatible with a number of DBW throttle bodies including GM, Chrysler, Ford, and Nissan Integrated dual channel wide band oxygen sensor controls Ì¢‰â‰Ûà For monitoring both engine banks (NTK or Bosch sensors) Extensive amount of inputs and outputs allow for limitless combination of options. Allows for unit to be used as a complete data acquisition system as well Individual cylinder fuel and spark control allows you to unlock your engineÌ¢‰â‰ã¢s potential 1-7 Bar MAP sensor capability Ì¢‰â‰Ûà For naturally aspirated or boosted applications Fuel Map and Learn Function Smoothing Ì¢‰â‰Ûà Helps to smooth rough areas of the maps Self-tuning fuel table strategy greatly simplifies tuning process Ì¢‰â‰Ûà The more you drive it, the more it learns Ì¢‰âÂÂÃ’Quick StartÌ¢‰âÂå strategies Ì¢‰â‰Ûà For faster engine starting Allows for use of common OEM sensors as well as custom sensor calibration input Two channel knock control sensor inputs for both one or two wire knock sensors Store and select between four calibrations with Multi Map Selector (Part Number 558-407) HARDWARE ECU is fully potted and can be mounted in the engine compartment or interior Ì¢‰â‰Ûà See images for dimensions Sealed automotive and marine grade connectors Optional Digital Displays - 7" Digital Dash (PN 553-106) / 3.5" Touch Screen LCD (PN 553-108) 12.3" Pro Dash (PN 553-111) and 7" Race Dash (PN 553-106) features full gauge layout customization, and nearly limitless tuning options. DATA VISUALIZATION TOOLS Data Logger Ì¢‰â‰ÛÃAnalyze and export your data with sophisticated, but user friendly tools Ì¢‰â‰Ûà Internal logger has 4 GB of memory Strip Chart Ì¢‰â‰Ûà For real-time data viewing Fully Configurable lap top Gauge Panel Ì¢‰â‰Ûà Life-like gauge cluster on your laptop screen Racepak Integration Module Available. Data logger - Smoothing, multiple graph view, pre-defined notes fields and more.. 8 STAGE NITROUS OXIDE CONTROL Fully featured nitrous control eliminates the need for a separate nitrous controller device Can be configured Ì¢‰âÂÂÃ’WetÌ¢‰âÂå or Ì¢‰âÂÂÃ’DryÌ¢‰âÂå with closed loop feedback Progressive control based on time, RPM, or boost, requires part # 554-111 Lean or rich safety cutoff Full timing retard/control configurability per stage based on RPM or time INTEGRATED WATER/METHANOL INJECTION CONTROL Uses Holley water/meth solenoids specially designed and calibrated for use with this EFI system to allow the user to enter water/meth flow as a percentage of fuel injector flow for water/meth tuning precision unmatched in the industry Allows for two nozzles to be controlled Nozzles available from 400 to 1000 cc/min Complete control of pump activation, and low system safety features TURBOCHARGER BOOST CONTROL Fully featured boost control capability eliminates the need for a separate boost control device Can be configured to control boost based on time, gear, speed, and manual inputs Gear based boost control configurable by several different methods Ì¢‰âÂÂÃ’Boost BuilderÌ¢‰âÂå functions offer the ability to assist building boost on the starting line by altering ignition timing, fueling, as well as nitrous oxide activation. Can also be used as an anti-lag function

All warranty questions, claims or otherwise should be directed toward the manufacturer